PVB

SHAPING AND CUTTING

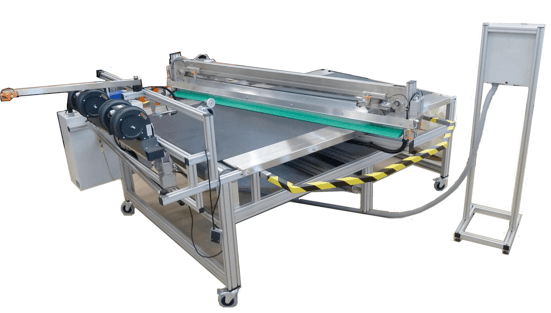

PVB conditioning for special applications

Used for:

PVB Conditioning line prepares PVB interlayer sheets for special applications requiring flat and shrinkage-free PVB, suc as PDLC screens. One application area is the production of car sunroofs.

It gives gives two benefits to the special laminate producer:

- Wrinkle-free PVB after conditioning.

- No shrinkage after conditioning and cutting.

Principe of operation:

The procedure uses PVB’s natural behavior from temperature differences.

Features:

According to the user’s needs :

- Real time process parameter management and recording

- Optional per sheet data collection

- Separate cutting with drive, operation width 1250 – 1750 mm

- Antistatic treatment of PVB

- Optional automatic PVB thickness measurement

Technical characteristics:

- Production speed 1-8m/min

- Standard width max 1750mm, other widths possible

- PVB shrinkage after conditioning: 0.2%

- Flat PVB after conditioning