Heatable Backlite

HEATABLE BACKLITE TECHNOLOGY

flexible soldering solutions for tempered and laminated glass

Heatable Backlite Technology

Used for:

Soldering and testing of heatable glass.

Principle of operation:

Softeco has a wide range of soldering and testing equipment for heatable glass production and quality control. The product range has been designed to fulfil different kinds of production requirements.

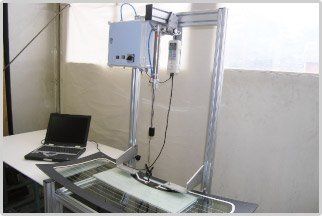

TESTING

Testing can be 100 %, random or statistical, on-line or off-line. We have suitable devices for testing a few pieces per day, and also for testing 500 pcs/h.

There is separate equipment for testing the electric circuit, the continuity of line, and the mechanical strength of the soldering. Some of the tests can be combined in one machine.

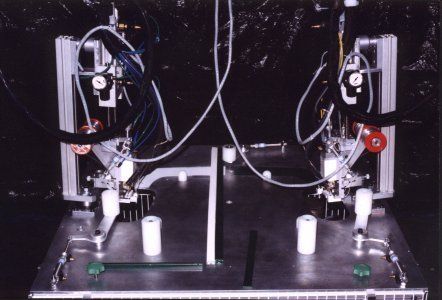

SOLDERING

For soldering, there is equipment with a capacity reaching 200 backlites per h and these stations can be multiplied, if needed. On the other hand, the manual soldering station is ideal for custom work, development or small-scale production.

To facilitate positioning and/or repeatability in manual or semi-automatic equipment, docking clamps or positioning jigs can be included.

GENERAL

All equipment is available as:

- manual

- semi-automatic

- custom automated

All automatic equipment can be modified to suit the customer’s production environment. Machine structures and layout can be modified according to customer needs.

The operational components, such as soldering heads, power supply units and electrodes are standardized to always give the same, reliable results.

Features:

TESTING

The electric circuit testing can be done:

- after tempering,

- after soldering, as random or 100 % control on-line or off-line

- in the laboratory, for the localization of line cuts and/or development

- the shearing or pull test can be non-destructive, or destructive.

SEMI-AUTOMATIC EQUIPMENT

The semi-automatic machines can be modified to some extent, taking into account for example :

- number of connectors on the backlite

- number of operators available

- unloading conveyors instead of manual unloading (location and type of soldering / testing)

MANUAL EQUIPMENT

Manual machines are standard, ready - to - use equipment without complicated installation procedures, equipped with automated soldering or testing cycles.

SOLDERING

Soldering can be done :

- after tempering, on warm glass ( on - line )

- after testing of silkprinted electric circuit, on cool glass ( off - line )

- at the glass producer’s premises or in the delivery and conditioning center near the end customer’s facilities.

TESTING

The electric circuit testing can be done :

- after tempering

- after soldering

- in the laboratory